Free Delivery On Orders Over £200 to UK Mainland

- Biological Microscopes

- Materials Microscopes

- Stereo Microscopes

- Category

- AREA OF INTEREST

- Life Sciences & Research

- University teaching laboratories

- Education & Students

- Materials & Industrial Inspection

- Entomology

- Mycology

- Jewellers & Watchmakers

- Hobbyist & Amateur Microscopists

- Drosophila Research

- Nematode Research

- Zebrafish Research

- Plant Sciences

- Medical

- PCB Inspection & Mobile Phone Repair

- Archaeology

- Forensics

- Palaeontology

- Artwork Curators

- Microfossils

- Wafer Inspection

- BRANDS

- PARTS & ACCESSORIES

- Digital Microscopes

- Cameras

- Polarising Microscopes

- Accessories

- CATEGORY

- Microscope Cameras

- Microscope Stands

- Camera Adapters

- Microscope Illuminators

- Microscope Slides & Coverslips

- Microscope Specimens

- Microscope Slide Storage

- Image Analysis

- Microscope Cases

- Calibration Slides, Micrometers & Reticles

- Microscopy Software

- Microscope Parts

- Magnifiers

- Microscope Motorisation

- Microtomes

- Anti Vibration Bases

- CATEGORY

- Area Of Interest

- CATEGORY

- Archaeology

- Artwork Curators

- Asbestos Identification & Counting

- Bacteria

- Biological Microscopes

- Blood Analysis

- Breweries – Yeast Inspection

- Children’s & Gift Microscopes

- Clinical, Histology & Pathology

- Conservation & Restoration

- Drosophila Research

- Earth Science, Geology, Minerals & Ores

- Education & Students

- ENT, Microsurgery & Dentists

- Entomology

- Environmental Microscopes

- Faecal Worm Microscopes

- Fertility Checking

- Forensics

- Hobbyist & Amateur Microscopists

- Jewellers & Watchmakers

- Life Sciences & Research

- Materials & Industrial Inspection

- Medical

- Metallurgy

- Microfossils

- Mycology

- Nematode Research

- Palaeontology

- Particle Sizing

- PCB Inspection & Mobile Phone Repair

- Plant Sciences

- Toxicology Microscopes

- University Teaching Laboratories

- Vets & Breeders

- Wafer Inspection

- Zebrafish Research

- CATEGORY

- Special Offers

- ALL PRODUCTS

- Home

- Biological Microscopes

- Materials Microscopes

- Stereo Microscopes

- Category

- AREA OF INTEREST

- Life Sciences & Research

- University teaching laboratories

- Education & Students

- Materials & Industrial Inspection

- Entomology

- Mycology

- Jewellers & Watchmakers

- Hobbyist & Amateur Microscopists

- Drosophila Research

- Nematode Research

- Zebrafish Research

- Plant Sciences

- Medical

- PCB Inspection & Mobile Phone Repair

- Archaeology

- Forensics

- Palaeontology

- Artwork Curators

- Microfossils

- Wafer Inspection

- BRANDS

- PARTS & ACCESSORIES

- Digital Microscopes

- Cameras

- Polarising Microscopes

- Accessories

- CATEGORY

- Microscope Cameras

- Microscope Stands

- Camera Adapters

- Microscope Illuminators

- Microscope Slides & Coverslips

- Microscope Specimens

- Microscope Slide Storage

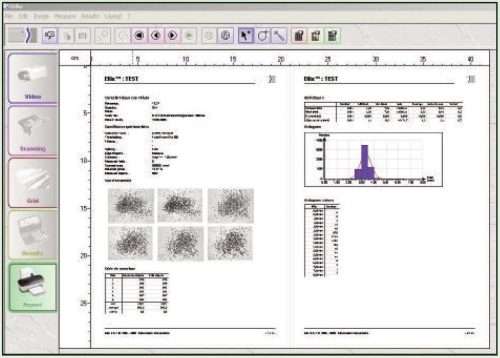

- Image Analysis

- Microscope Cases

- Calibration Slides, Micrometers & Reticles

- Microscopy Software

- Microscope Parts

- Magnifiers

- Microscope Motorisation

- Microtomes

- Anti Vibration Bases

- CATEGORY

- Area Of Interest

- CATEGORY

- Archaeology

- Artwork Curators

- Asbestos Identification & Counting

- Bacteria

- Biological Microscopes

- Blood Analysis

- Breweries – Yeast Inspection

- Children’s & Gift Microscopes

- Clinical, Histology & Pathology

- Conservation & Restoration

- Drosophila Research

- Earth Science, Geology, Minerals & Ores

- Education & Students

- ENT, Microsurgery & Dentists

- Entomology

- Environmental Microscopes

- Faecal Worm Microscopes

- Fertility Checking

- Forensics

- Hobbyist & Amateur Microscopists

- Jewellers & Watchmakers

- Life Sciences & Research

- Materials & Industrial Inspection

- Medical

- Metallurgy

- Microfossils

- Mycology

- Nematode Research

- Palaeontology

- Particle Sizing

- PCB Inspection & Mobile Phone Repair

- Plant Sciences

- Toxicology Microscopes

- University Teaching Laboratories

- Vets & Breeders

- Wafer Inspection

- Zebrafish Research

- Special Offers

- CATEGORY

- SERVICE & REPAIR

- GT Vision Membership

- BLOG

- Contact Us & Jobs

- ABOUT US

Reviews

There are no reviews yet.